The Impact of GNSS Systems on Global Supply Chain and Logistics

Global Navigation Satellite Systems (GNSS) have become essential tools in modern logistics, significantly transforming the way supply chains operate. By providing accurate, real-time geospatial data, GNSS system enhance efficiency, reduce operational costs, and improve the overall transparency of the global supply chain. This article explores how GNSS systems impact global supply chain and logistics, highlighting key benefits and challenges.

What is GNSS and How Does It Work?

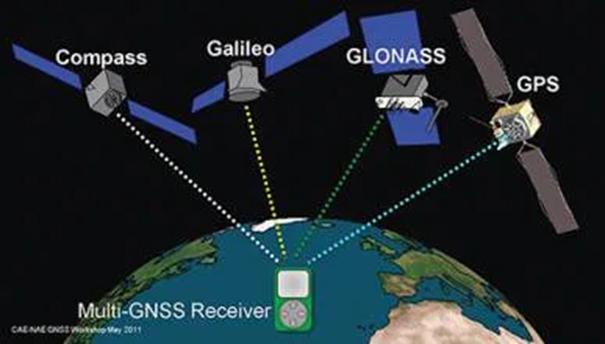

GNSS refers to a collection of satellite-based navigation systems that provide positioning, navigation, and timing data to users worldwide. The most well-known GNSS systems include:

- GPS (Global Positioning System) from the United States

- GLONASS from Russia

- Galileo from the European Union

- BeiDou from China

These systems work by utilizing a constellation of satellites orbiting the Earth. GNSS receivers on the ground (in vehicles, shipping containers, or warehouses) receive signals from these satellites and calculate the receiver’s precise location, speed, and time.

GNSS Systems and Their Role in Supply Chain Management

1. Real-Time Tracking and Visibility

One of the most significant advantages of GNSS systems in logistics is real-time tracking. Supply chain managers can now monitor shipments in transit at every stage of the journey. Whether goods are on a ship crossing the ocean, a truck traveling across land, or an airplane in the air, GNSS systems provide pinpoint accuracy, enabling businesses to track the location and condition of their assets with high precision.

- Enhanced Transparency: Businesses can offer customers more transparency regarding delivery times, location, and expected arrival.

- Improved Communication: Real-time data allows for better coordination between suppliers, warehouses, transporters, and retailers.

2. Route Optimization and Efficiency

GNSS systems allow logistics companies to optimize delivery routes by providing up-to-the-minute data about traffic, road conditions, and potential delays. GPS-based route planning enables vehicles to avoid congestion and adverse weather, thereby reducing transportation time and fuel consumption.

- Cost Savings: Optimized routes reduce fuel costs and minimize unnecessary delays.

- Environmental Impact: By reducing fuel consumption, logistics companies can also decrease their carbon footprint, contributing to sustainability efforts.

3. Asset Management and Security

In the global supply chain, theft or misplacement of goods is a major concern. GNSS systems provide a solution by offering real-time geolocation of shipments and assets. This means that in the event of theft or diversion, logistics companies can quickly pinpoint the location of their goods and take action.

- Enhanced Security: GNSS systems can trigger alerts if an asset moves outside its designated route or location.

- Inventory Management: Accurate location data helps businesses manage stock levels, reducing the chances of understocking or overstocking.

4. Supply Chain Synchronization

Global supply chains often involve numerous stakeholders, from manufacturers to distributors, retailers, and end customers. GNSS data helps synchronize all aspects of the supply chain by providing a common point of reference. For instance, when a shipment is delayed due to weather or logistical challenges, GNSS allows for timely adjustments across the entire supply chain, preventing disruptions.

- Coordinated Operations: GNSS enables seamless communication across various parties involved, reducing inefficiencies.

- Proactive Problem Solving: The system allows for quicker identification of potential delays, helping businesses make proactive changes to prevent disruptions.

Challenges and Limitations of GNSS in Supply Chain and Logistics

Despite the many benefits of GNSS systems, their implementation does come with challenges.

1. Signal Interference

One of the primary challenges with GNSS systems is the potential for signal interference. Urban environments with tall buildings, remote regions with limited satellite coverage, or areas with heavy machinery can disrupt the signal, leading to reduced accuracy or temporary loss of tracking data.

2. High Initial Investment

While GNSS technology has become more affordable over time, the initial investment for setting up a global tracking system—especially for large fleets—can be expensive. Businesses must consider the cost of hardware, software, and ongoing maintenance.

3. Data Privacy Concerns

As GNSS systems provide detailed location data, they raise concerns over the privacy of sensitive information. Companies need to ensure that the data they collect is protected and used responsibly to avoid any security breaches.

Future Trends in GNSS and Logistics

The role of GNSS systems in supply chain and logistics is only expected to grow in the coming years. Some trends to look out for include:

1. Integration with IoT and Big Data

The integration of GNSS with Internet of Things (IoT) devices and big data analytics will offer even more comprehensive insights into logistics operations. This could include automatic adjustments to routes based on weather patterns, predictive maintenance for vehicles, and real-time monitoring of cargo conditions (e.g., temperature, humidity).

2. Enhanced Autonomous Systems

GNSS is critical for the development of autonomous vehicles in the logistics industry. Self-driving trucks and drones rely on precise location data to navigate roads and deliver goods. As GNSS technology advances, the efficiency and safety of these autonomous systems will continue to improve.

3. Next-Generation Satellite Systems

Next-generation GNSS systems, such as the upcoming Galileo and BeiDou upgrades, will offer even more accurate and reliable positioning data. These advancements will reduce errors in location tracking, leading to greater efficiency in supply chain management.

Conclusion

The impact of GNSS systems on the global supply chain and logistics sector is profound. These systems provide real-time tracking, route optimization, better asset management, and improved synchronization across various supply chain partners. While there are challenges such as signal interference and privacy concerns, the continued development and integration of GNSS with emerging technologies like IoT and autonomous vehicles promise to drive even greater efficiencies in the future. As businesses around the world continue to embrace GNSS technology, the logistics industry is set to become more connected, efficient, and sustainable.